Guangdong Lingguan Energy-saving New Materials Co., Ltd. will exhibit at the 2021 China International Refrigeration and Cold Chain Exhibition (RACC2021) to be held at the Hangzhou International Expo Center from October 22-24. At that time, the company will exhibit cold storage board products, and welcome new and old customers to visit booth 1C-M25 to consult and discuss cooperation.

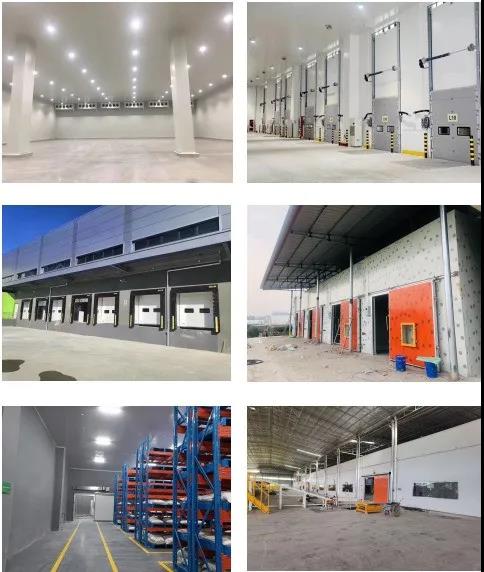

Guangdong Lingguan Energy-saving New Materials Co., Ltd. is a large-scale comprehensive production enterprise integrating R&D, design and production of polyurethane cold storage insulation panels, polyurethane exterior wall sandwich panels, and polyurethane manual panels. The panels are suitable for industrial freezers, food freezers, and fruit and vegetable gas Storage, high and low temperature freezer, logistics cold storage, ship cold storage, large ski resort, food purification processing workshop, as well as steel structure building exterior panels, energy-saving workshops and other fields.

Obtained international environmental protection certification, products are widely applicable

The company's products are rich and diverse, and the refrigeration warehouse project can be ordered according to needs

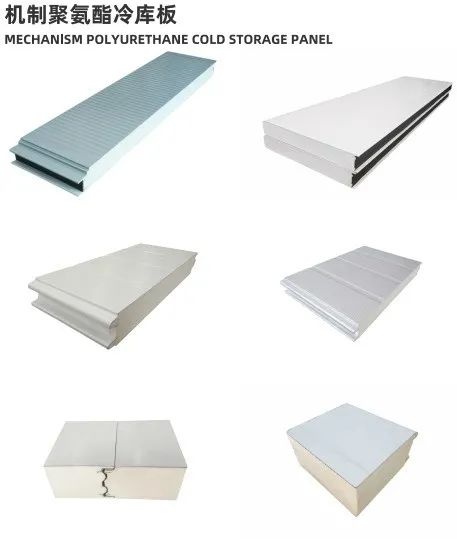

PUR polyurethane insulation board

PUR polyurethane insulation board core material is the product of the reaction of polyisocyanate and polyether or polyester polyol in a certain proportion.

PUR sandwich panel characteristics: low thermal conductivity, low water absorption, good thermal insulation performance, high compressive strength, not easy to deform, widely used in the maintenance structure of modular cold storage.

PIR polyisocyanurate insulation board

PIR polyisocyanurate insulation board core material, also known as polyisocyanurate foam, is the product of the trimerization reaction of isocyanate itself.

PIR sandwich panel characteristics: Compared with PUR sandwich panel, IR has lower thermal conductivity and better fire resistance. It is also increasingly used in the maintenance structure of cold storage.

The plug-in insulation board produced by the company adopts the international advanced fully automatic continuous production line, and the foam material is in the high temperature environment.

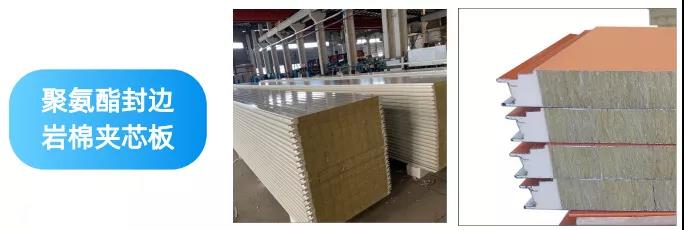

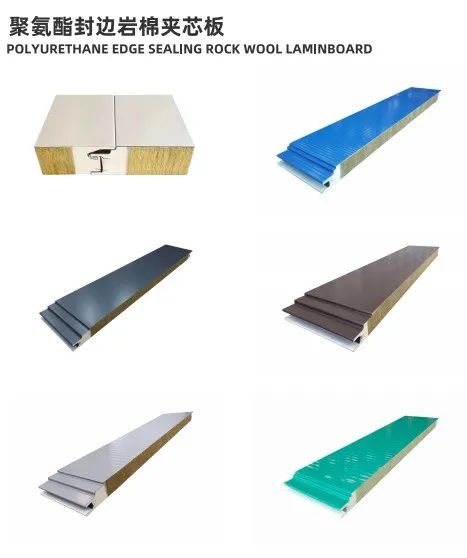

Polyurethane edge-sealed rock wool sandwich panel

Polyurethane edge-sealed rock wool sandwich panel has low thermal conductivity, good load resistance, high bending strength, no water absorption, no rot, no insect bites, good flame retardancy, and wide temperature resistance range. Using the physical properties and unique formula of polyurethane (PU.R), the polyurethane foaming agent is evenly sprayed on the color-coated steel plate, so that the foaming agent is foamed between the color-coated steel plates into a three-layer disposable polyurethane ( PU.PR) Color steel composite sandwich panel. This new light-weight building material is the perfect combination of color-coated steel plate and polyurethane, and is the development direction of light-weight building materials.

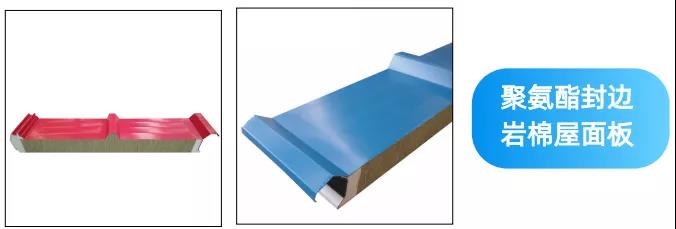

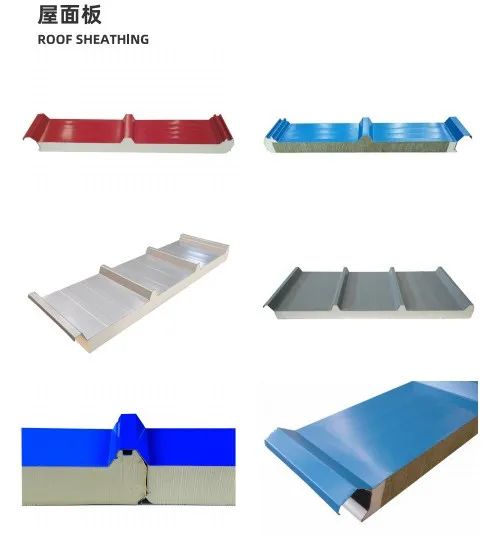

Polyurethane edge-sealed rock wool roof panel

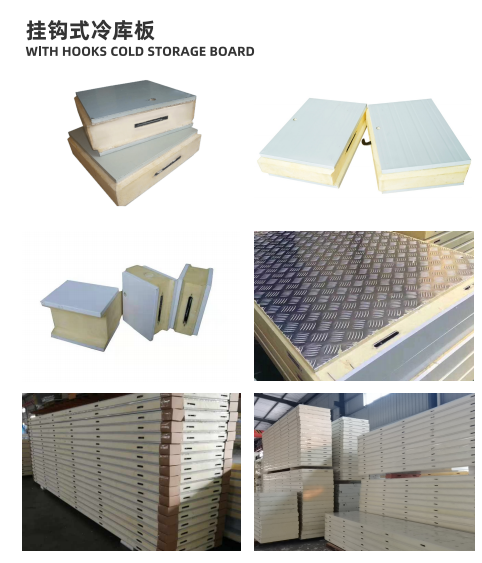

Eccentric hook plate

The structure of the eccentric hook plate is a polyurethane sandwich panel made with a traditional mold. The eccentric hook is embedded in the mold during production, and the eccentric hook is embedded around the core plate to facilitate splicing. It is generally suitable for small or medium-sized cold storage.

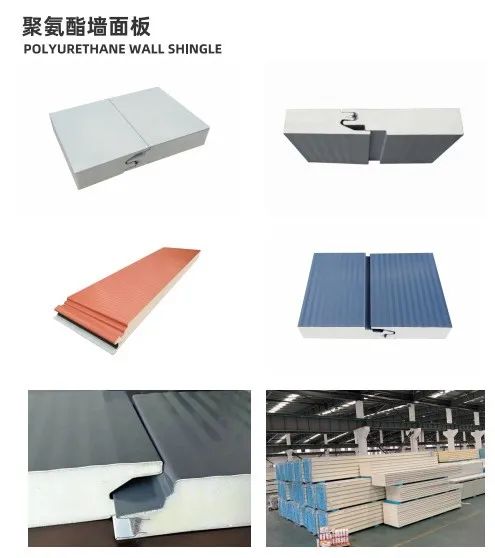

Products display

冷库工程案例